Consultation

Do you have specific technical requirements and

need a customized solution?

From planning to implementation, we offer expert consultation. We are happy to create custom designs for extreme applications.

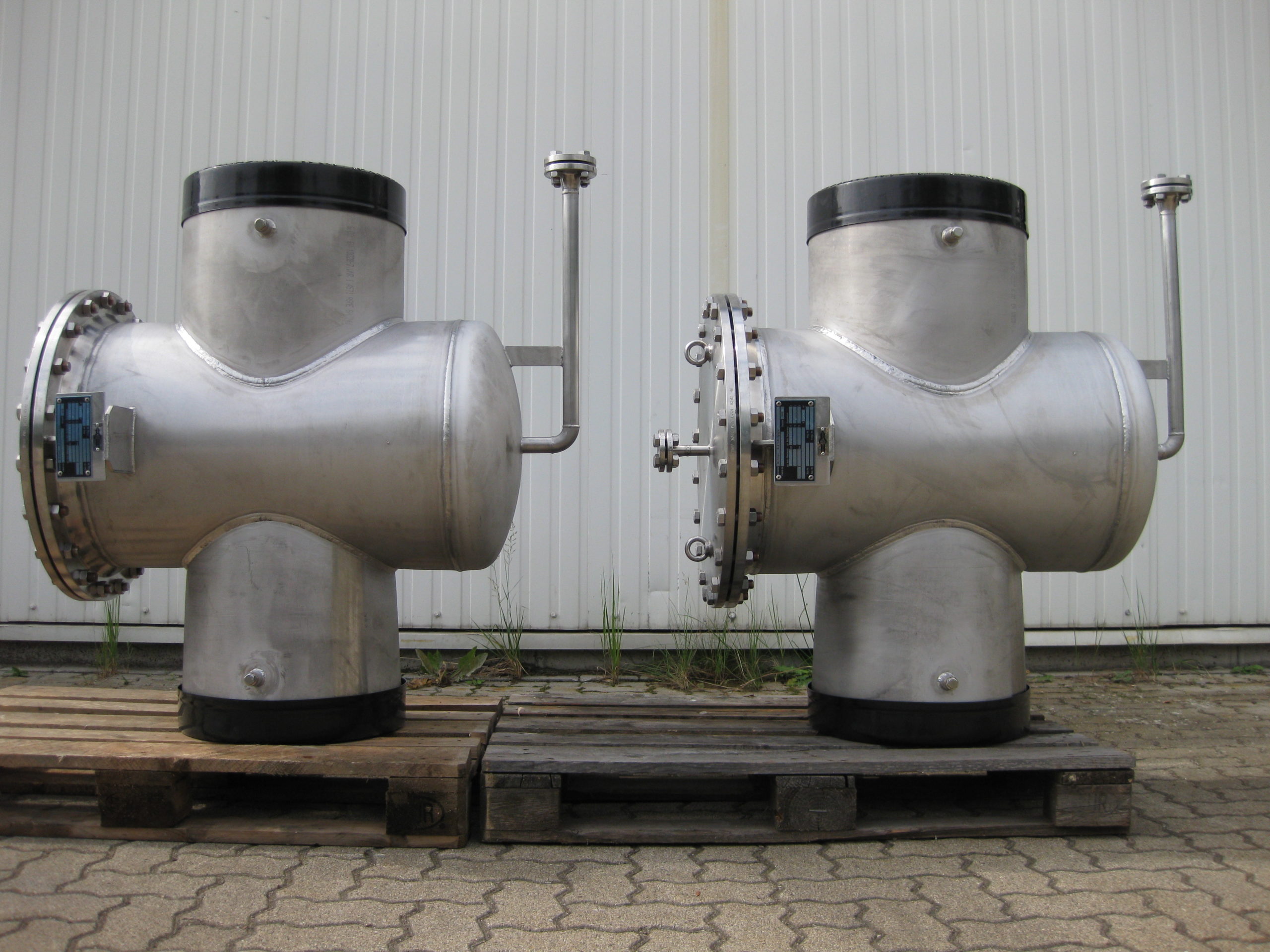

The welded construction of our strainers allows for custom lengths, the use of high-temperature-resistant and stainless steel grades, flange and weld-in designs, as well as pressure rating configurations according to DIN EN 1092-1 and ANSI B 16.5.

Options for mounting ex works

Under the Accessories > section, you will find options for factory installation of equipment components, such as pressure gauges for differential pressure monitoring.

10 tips for planning strainers / filters:

1. Low resistance value (zeta)

1. Low resistance value (zeta)

safe energy cost & increase efficiency

= annual energy savings ≥ buying price

2. Large effective Filtering area

2. Large effective Filtering area

most important figure = size of filtering area provided into the stream, but not the installed filtering area – as usually highlighted in brochures

3. Angle of impact between flow and sieve

3. Angle of impact between

flow and sieve

sieve with impact angle of 90⁰ will clock easier as with flat impact angle lengthening cleaning and maintenance intervals

4. Closed sieve-body

4. Closed sieve-body

Using an open sieve, filtered particles will remain in housing of strainer

→ triggers additional unnecessary cleaning effort

5. Easy applicability of the strainer

5. Easy applicability of the strainer

both horizontal and vertical applicability simplifying the pipeline layout

6. Good handling of top flange (cover)

6. Good handling of top flange (cover)

→ swivel/swing arm: strainer of larger dimensions (top flange >20kg) maintenance personnel experiences it less exhausting and time consuming

7. Weldable housing material

7. Weldable housing material

consider welding type strainer already in design phase → lower cost for/isolation and excluding potential leakage points

8. Gaskets for manometers

8. Gaskets for manometers

Strainer that are functioning do increase their pressure loss in time; necessary to gain information on the level of dirt within the strainer.

9. Filtering fineness

9. Filtering fineness

plan the sieve: “as coarse as necessary and as fine as possible!”

10. Sealing of the top flange (cover)

10. Sealing of the top flange (cover)

The only consumable part of a good strainer shall be the cover sealing

→ make sure, commercially available seals are used